Distillers Building

Distillers Building

Smithfield

The Office of Public Works (OPW), which manages much of the State’s property portfolio, has let the 15,094 sq m Distiller’s building in Smithfield . Prominently located beside the Smithfield Luas stop and Smithfield Plaza, the OPW plans to house two major Government organisations, including the Chief State Solicitors Office, in the building.

The development’s sustainably focussed HVAC system has been designed by Varming Consulting Engineers and implemented by T-Bourke & Co. Keane Environmental were delighted to supply Diffusion fancoils, Damvent Hybrid AHUs, Gilberts Grilles and Pettinaroli PICVs.

Energy Efficiency at the Core

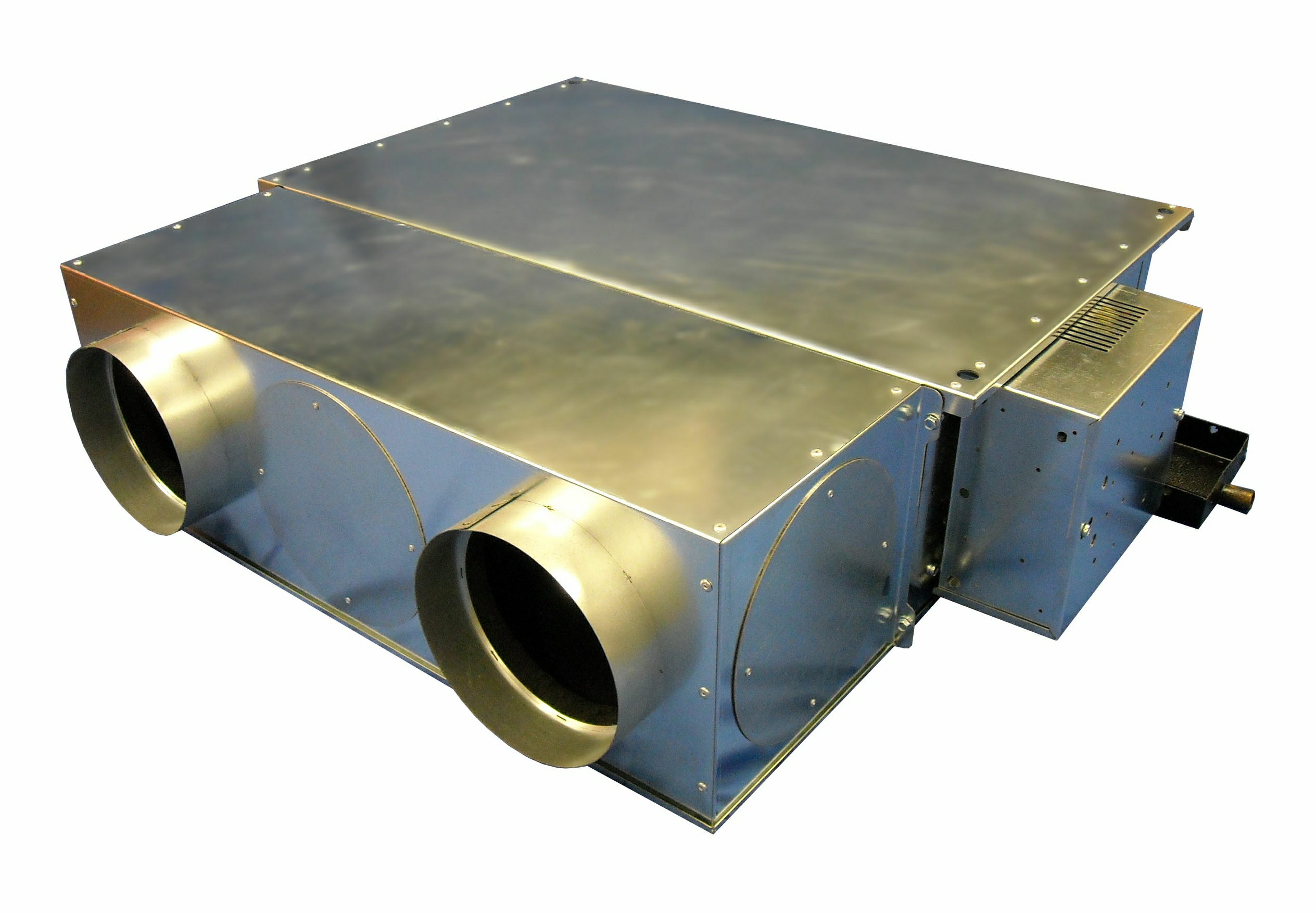

This project is driven by a commitment to energy efficiency, evident in every design decision and specification. With stringent energy rating criteria demanding best-in-class Specific Fan Power (SFP) levels, the Diffusion 270EC Fan Coil was selected for its superior efficiency. By incorporating this cutting-edge technology, Varmings and T-Bourke ensured optimal air circulation and occupant comfort while significantly reducing the building’s environmental impact.

Precision Air Distribution with Gilberts Grilles & Diffusers

In areas with suspended ceilings, Gilberts GZL and GSL Slot Diffusers were installed, while GSFP diffusers with Coanda plates were used in spaces with exposed services. Gilberts grilles undergo rigorous testing to guarantee efficient air distribution, maintaining optimal ventilation and indoor comfort.

For areas without suspended ceilings, Coanda plates enhance airflow by utilizing the Coanda effect, which directs air along the ceiling for better mixing and even distribution. In industrial-style spaces with exposed services—such as the Distillers Building in Smithfield—this combination seamlessly integrates with the aesthetic while delivering high-performance thermal comfort and air quality.

Damvent: Pioneering Hybrid AHU Technology

Damvent was the first company to formally introduce COPnet/COPsystem efficiency calculations in official documentation and software, establishing a new industry standard now followed by others:

This formula evaluates the total net efficiency of Hybrid Integrated Fresh Air Solutions, ensuring optimized performance.

What is a Hybrid AHU?

A Hybrid Air Handling Unit (AHU) integrates all heating and cooling components within a single unit, eliminating the need for external connections. It includes:

- Internal condenser & evaporator coils

- Built-in compressors, heat recovery, and controls

- No external heating or cooling connections required

- Heat recovery exceeding 100% under optimal conditions

Hybrid technology incorporates two heat recovery methods:

- Passive: Thermal wheel or cross-plate heat exchanger

- Active: Built-in heat pump with a condenser in the exhaust air path

Key Advantages of a Hybrid AHU

✔ Reduced Carbon Footprint – No external pipework – No need for chilled water (ChW), low-pressure hot water (LPHW), or refrigerant connections

✔ Pre-charged refrigerant – No on-site refrigerant work required

✔ Reduced footprint – Eliminates the need for external chillers, boilers, or condensers

✔ Plug & play control system – Fully self-contained for maximum efficiency in all conditions

✔ BMS compatibility – Can integrate with building management systems or operate standalone

✔ High thermal energy recovery – Condensers located in the return air path achieve efficiencies exceeding 100%

✔ Continuous operation – No electric heating elements required for defrosting in standard applications

✔ Dehumidification option – Available without electric heating elements

This next-generation AHU solution delivers unmatched efficiency, sustainability, and ease of integration for modern building environments.

Pettinaroli PICV Assemblies

Pettinaroli’s versatile range of PICV assemblies for fan coils, offers significant benefits over standard products.

Pettinaroli’s pre-fabricated valve assemblies ensure that everything required for a successful connection is supplied in one package.

Features:

- Proven Reliability on many Irish & European Projects

- Designed for direct connection to Fan Coil Units

- Engineered for Optimal Performance in Challenging Water Systems

- Compact Design

- Full Bore Drain

- Configurable Connections

- All Components Manufactured in Italy.

Questions?

At Keane Environmental Ltd., we understand that every job, large or small, has its own challenges. We’d be delighted to work with you to find the correct solution for your building. If you’d like to hear more about this or any of our other projects, contact us today.

Consulting Engineers: Varming Consulting Engineers

Mechanical Contractor: T Bourke

Client: OPW

Suppliers: Keane Environmental Ltd.